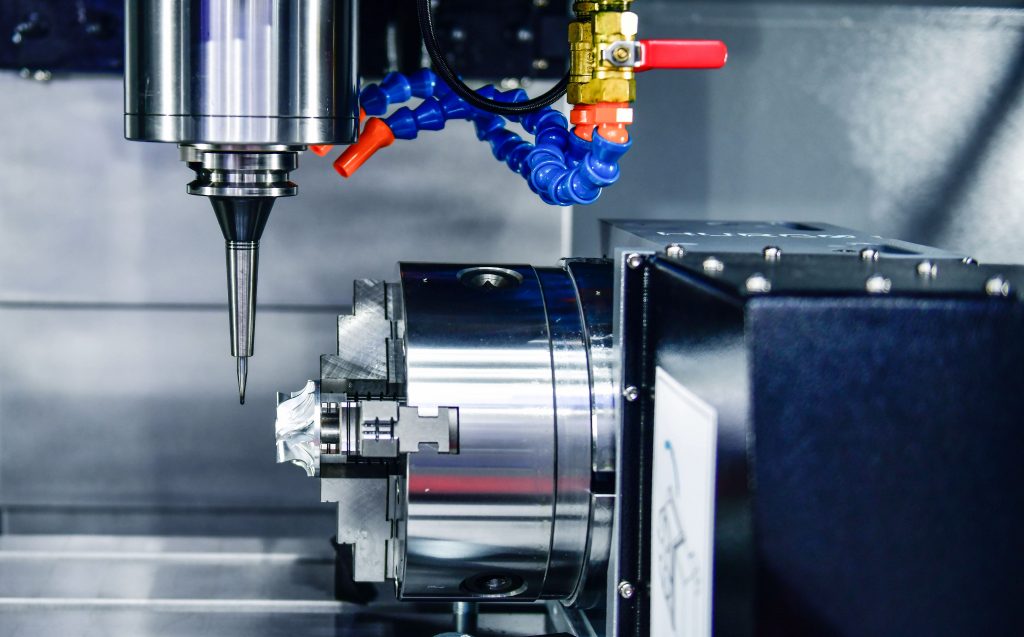

Modern manufacturing increasingly demands the ability to produce complex, high-precision components efficiently and consistently. The 5-axis milling machine was developed to meet exactly those requirements. By reducing the need for multiple setups and manual repositioning, it enables the machining of intricate geometries that would otherwise be difficult or impossible to achieve. Understanding how 5-axis milling works helps explain why it has become a key technology across industries such as aerospace, medical, and automotive manufacturing.

What is a 5 axis milling machine

A 5-axis milling machine is a type of CNC milling system that moves a cutting tool or workpiece along five different axes simultaneously—typically the X, Y, and Z linear axes, plus two rotational axes (A and B or A and C). This configuration allows the tool to approach the part from virtually any direction, making it possible to machine complex contours, undercuts, and curved surfaces in a single operation.

There are two main types of 5-axis cnc machines: head–head configuration, where both rotational axes are within the spindle head, providing maximum flexibility for smaller parts, and table–table or head–table configuration, where rotation occurs on the worktable or a combination of head and table axes—often preferred for larger or heavier components. This multi-axis capability eliminates the need to reposition the workpiece manually, maintaining geometric accuracy and reducing total machining time.

Benefits of 5-axis milling machine

- Single-setup machining – Complex parts can be fully machined in one setup, automating the process and eliminating repositioning errors while reducing fixture requirements. This not only improves dimensional accuracy but also streamlines production by removing the need for multiple clamping stages. By reducing setup time and manual handling, manufacturers can achieve faster turnaround and consistent part alignment across batches.

- Higher precision – Continuous tool engagement and reduced manual intervention minimize tolerance stack-up and maintain accuracy across multiple surfaces. By machining all sides of a component in a single cycle, 5-axis systems ensure perfect geometric relationships between features. This precision is especially valuable in applications where even minor deviations can affect assembly or performance, such as aerospace components or precision molds.

- Complex geometry capability – Ideal for parts with intricate shapes, deep cavities, or undercuts that would otherwise require multiple setups or specialized tooling. The ability to move along and around the part enables manufacturers to produce freeform surfaces, organic contours, and compound angles with ease. This versatility expands design possibilities and reduces the need for secondary machining operations.

- Improved surface finish – The ability to maintain a constant tool angle and uniform chip load minimizes tool marks and surface irregularities. This results in smoother, more consistent finishes across curved or contoured surfaces. Reduced vibration and optimized tool orientation also minimize heat generation, which can otherwise affect surface quality and material integrity.

- Shorter lead times – Fewer setups, efficient toolpaths, and the ability to handle complex parts in one operation significantly shorten production cycles. High-speed spindles and simultaneous multi-axis motion reduce idle time between processes, enabling manufacturers to move from prototype to finished part more quickly. This efficiency makes 5-axis machining especially valuable for industries working with tight deadlines or high-mix, low-volume production.

- Tool life and efficiency – Maintaining the optimal cutting angle during machining distributes tool wear more evenly and reduces stress on cutting edges. This not only extends tool life but also allows for more aggressive cutting parameters without compromising accuracy. The result is greater material removal efficiency, lower tooling costs, and improved overall process reliability.

Key components of 5-axis milling machines

- Base and column – Provide rigidity and stability to absorb cutting forces. The mechanical stiffness of these components directly influences surface finish and accuracy. In 5-axis machines, the base and column are often reinforced with high-mass materials such as cast iron or polymer composites to dampen vibration and maintain precise alignment during complex multi-axis movements. Their robust construction is essential for ensuring long-term machine stability and repeatable accuracy under demanding cutting conditions.

- Spindle and motor – Deliver rotational power to the cutting tool. High-speed spindles with precision bearings enable fine finishing and high-efficiency machining. Many 5-axis milling machines use direct-drive or built-in motor spindles for smoother acceleration, improved torque control, and minimal heat buildup. Variable-speed control allows the spindle to adapt to different materials—from aluminum to titanium—ensuring optimal cutting performance and extended tool life.

- Rotary axes (A, B, or C) – Allow angular movement of either the tool or workpiece. These are typically driven by direct-drive motors for smooth, backlash-free rotation. The rotary axes enable the tool to approach the workpiece from multiple orientations, making it possible to machine complex geometries and undercuts without reclamping. Their precision and synchronization with linear axes are critical for maintaining accurate toolpaths and consistent surface finishes.

- Worktable – Supports and positions the workpiece during machining. Some 5-axis tables feature tilting and rotating mechanisms to dynamically orient the part while cutting, improving tool access and efficiency. Precision-engineered rotary tables can handle heavy loads while maintaining smooth, controlled motion, making them essential for machining large molds, turbine components, and complex aerospace structures.

- Tool changer – Automatically switches between cutting tools, enabling multiple operations—such as roughing, finishing, and drilling—in one continuous cycle. Advanced tool changers can hold dozens or even hundreds of tools, allowing for flexible, uninterrupted machining. They minimize operator intervention, reduce idle time, and improve productivity—especially in high-mix production environments requiring frequent tool changes.

- CNC control unit – The central system that interprets 5-axis G-code and coordinates simultaneous motion. Advanced controllers include dynamic tool compensation, collision detection, and real-time kinematic correction. They manage complex motion algorithms to synchronize all five axes, ensuring accurate, collision-free toolpaths. Modern control units also integrate with CAD/CAM systems and digital monitoring platforms, enabling rapid simulation, remote diagnostics, and adaptive machining for continuous precision.

How a 5-axis milling machine works

The working principle of a 5-axis milling machine is based on synchronized motion across five axes. The cutting tool can move linearly along X, Y, and Z while simultaneously rotating around two perpendicular axes. This coordinated motion enables the tool to maintain the optimal cutting angle relative to the work surface throughout the machining process.

The workflow typically includes:

- CAD/CAM programming – The part is first designed in CAD software, then processed in CAM software, where toolpaths are generated for 5-axis movement. These paths are converted into G-code that defines the tool’s trajectory and cutting parameters.

- Machine setup – The workpiece is mounted securely on the table, often using precision fixturing or vacuum systems. Proper setup minimizes deflection and ensures alignment with the machine coordinate system.

- Toolpath execution – The CNC controller synchronizes movements along all five axes, maintaining optimal tool orientation to the workpiece surface. This results in consistent cutting conditions, improved surface finish, and reduced tool wear.

- Monitoring and feedback – Sensors and feedback systems monitor spindle loads, tool position, and vibration in real time, allowing automatic adjustments for stable cutting performance and dimensional accuracy.

Applications of 5-axis milling machines

5-axis milling technology is widely used across industries that require complex and high-precision components.

- Aerospace – Turbine blades, impellers, and structural airframe components with contoured surfaces.

- Medical – Orthopedic implants, dental prosthetics, and surgical tools with intricate geometries.

- Automotive – Engine components, molds, and high-performance parts requiring exact tolerances.

- Energy – Turbine housings, pump impellers, and precision fittings for power generation systems.

- Tool and die – Injection molds, press tools, and precision dies requiring smooth surfaces and accurate contours.

Conclusion

5-axis milling machines represent a major advancement in machining capability, combining flexibility, precision, and efficiency in a single system. Their ability to cut complex shapes from multiple angles reduces production time, improves part quality, and expands the possibilities of modern design. As technology continues to evolve, features such as adaptive control, real-time monitoring, and digital integration will further enhance their performance. For manufacturers seeking to balance accuracy with productivity, 5-axis milling remains one of the most effective solutions available.