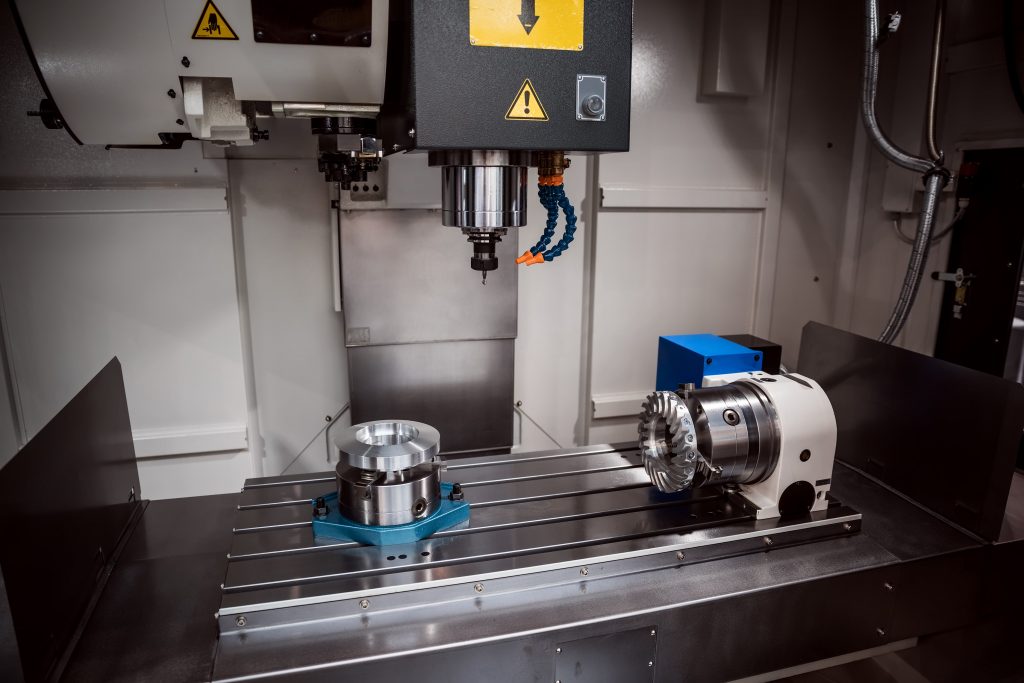

CNC machining has become one of the most widely used manufacturing methods in modern industry. Its ability to transform digital designs into precise, repeatable physical parts makes it indispensable across aerospace, automotive, medical, and many other sectors. But how exactly does the CNC machining process work, and what makes it so effective?

What is CNC machining

CNC (computer numerical control) machining is a subtractive manufacturing process in which pre-programmed software controls the movement of machine tools such as mills, lathes, and grinders. Instead of relying on manual operation, CNC machines execute instructions automatically, allowing for higher precision, faster cycle times, and consistent quality.

At the core of CNC machining is the conversion of a digital model into a set of instructions (known as G-code) that tells the machine exactly how to move the tool, at what speed, and to what depth, in order to remove material and produce the final part.

How does cnc machining work step by step

Design and programming

Every CNC process begins with a digital model of the component, created in CAD (computer-aided design) software. The model defines the geometry, dimensions, and tolerances of the part. This file is then imported into CAM (computer-aided manufacturing) software, where engineers select cutting tools, feeds, speeds, and machining strategies based on the material and required accuracy. The CAM system generates a G-code program—a sequence of instructions that defines every motion of the cutting tool. At this stage, simulation is often used to verify toolpaths, check for collisions, and optimize machining time before anything is physically cut.

Machine setup

Once programming is complete, the operator prepares the CNC machine. This includes securely mounting the raw material (workpiece) on the machine table, a fixture, or a vise to ensure rigidity during cutting. Cutting tools are installed into the spindle or automatic tool changer (ATC), and offsets are established so the machine knows the exact position of both the workpiece and the tools relative to its coordinate system. Accurate setup is essential, as even small misalignments can affect tolerances and surface finish.

Execution of G-code

The CNC controller acts as the “brain” of the system, reading the G-code line by line and converting the commands into precise movements. It sends signals to servo motors, stepper motors, and actuators, which control the spindle speed, axis movements, tool changes, and coolant delivery. Unlike manual machining, where accuracy depends on operator skill, CNC control ensures repeatability across multiple parts with minimal variation.

Material removal

The programmed cycle begins with the cutting tool engaging the workpiece. Depending on the type of CNC machine, this could involve CNC milling, turning, drilling, tapping, grinding, or EDM (electrical discharge machining). Material is removed progressively, either in roughing passes to remove bulk material quickly or in finishing passes to achieve the final dimensions and surface quality. Advanced strategies such as high-speed machining or adaptive toolpaths optimize cutting efficiency while reducing tool wear.

Monitoring and feedback

Modern CNC machines are equipped with sensors and closed-loop feedback systems that monitor spindle loads, axis positions, vibrations, and tool conditions. Probing systems can measure the workpiece mid-cycle, automatically adjusting toolpaths if deviations are detected during the CNC machining process. This real-time monitoring ensures that even complex parts stay within tight tolerances and reduces the risk of scrapped components.

Finished part and inspection

After machining, the workpiece is removed from the fixture and typically undergoes quality checks. Dimensional accuracy may be verified using calipers, micrometers, or CMMs (coordinate measuring machines). Surface finish and geometric tolerances are also inspected to ensure the part meets design specifications. In many cases, CNC machining produces parts with such high precision that no further processing is required, although secondary operations like heat treatment, coating, or polishing may be applied depending on the application.

Types of CNC machines

CNC technology is applied across a wide range of machine tools, each designed for specific operations and part geometries. The main types of CNC machines include:

- CNC milling machines – Use rotary cutting tools to remove material from a stationary workpiece. Available in 3-axis, 4-axis, and 5-axis configurations, milling machines are highly versatile and capable of producing flat surfaces, pockets, slots, and complex 3D contours.

- CNC lathes and turning centers – Rotate the workpiece against a stationary or linearly moving cutting tool. Ideal for cylindrical parts, these machines are widely used to produce shafts, threads, tapers, and round profiles. Modern turning centers often include live tooling and sub-spindles for milling and drilling in a single setup.

- CNC drilling machines – Specialized for creating precise holes with controlled depth and spacing. High-speed drilling centers are commonly used in electronics, automotive, and aerospace applications where multiple holes must be produced quickly and accurately.

- CNC grinding machines – Use abrasive wheels to achieve high-precision surface finishes and tight tolerances. Grinding is often the final step in producing critical components such as bearing races, gears, and precision tooling.

- CNC electrical discharge machines (EDM) – Remove material using electrical discharges (sparks) rather than mechanical cutting. Wire EDM and die-sinking EDM are used for intricate shapes, hardened materials, and tool and die applications.

- CNC laser, plasma, and waterjet cutters – Use focused energy or high-pressure fluid streams to cut materials with precision. These are particularly useful for sheet metal fabrication, composites, and materials that are difficult to machine conventionally.

- CNC routers – Similar to milling machines but designed for softer materials such as wood, plastics, and composites. CNC routers are widely used in furniture making, sign production, and lightweight composite manufacturing.

Each type of CNC machine addresses specific production challenges, and many facilities use a combination of them to cover the full spectrum of machining needs—from roughing and shaping to finishing and cutting.

Why CNC machining is effective

- Automation reduces human error – By replacing manual intervention with computer-controlled movements, CNC machining minimizes mistakes caused by operator fatigue, inconsistency, or miscalculation. Once a program is validated, the machine executes it with the same precision every time, ensuring uniform results across shifts and operators.

- High precision and accuracy – CNC machines are capable of holding extremely tight tolerances, often within microns, which is critical for industries such as aerospace, automotive, and medical manufacturing. Precision comes not only from the mechanical design of the machines but also from advanced servo systems, feedback loops, and software control that keep tool motion exact.

- Flexibility in machining geometries – CNC machining can produce both simple components, like shafts and housings, and highly complex shapes with undercuts, contours, or freeform surfaces. With multi-axis configurations, even intricate parts that once required multiple setups or specialized tooling can now be completed in a single operation.

- Repeatability at scale – Once a part is programmed and the setup is established, CNC machines can produce identical components in large quantities without variation. This repeatability is vital for production environments where interchangeability and consistency are non-negotiable.

- Compatibility with digital workflows – CNC machining integrates seamlessly with CAD and CAM systems, bridging the gap between digital design and physical manufacturing. Engineers can quickly move from prototyping to full-scale production using the same digital models, reducing lead times and supporting agile product development. This also facilitates design optimization, simulation, and quality control in a fully digital environment.

Conclusion

CNC machining has transformed modern manufacturing by combining digital precision with automated control. Its ability to produce simple or highly complex parts with accuracy, consistency, and efficiency makes it indispensable across industries. By reducing errors, shortening lead times, and integrating seamlessly with digital workflows, CNC machining bridges the gap between design and production. As technology continues to advance, it will remain a cornerstone of precision engineering and a driver of industrial innovation.