The evolution of Computer Numerical Control (CNC) technology has completely reshaped modern manufacturing, enabling unmatched precision, efficiency, and repeatability across a vast range of applications. From intricate aerospace components to large industrial assemblies, CNC machines bring digital accuracy to every stage of production. Their ability to automate complex processes while maintaining micrometer-level tolerances has made them the foundation of today’s high-performance manufacturing environments. Understanding the different types of CNC machines reveals how each contributes uniquely to shaping the products that power our world.

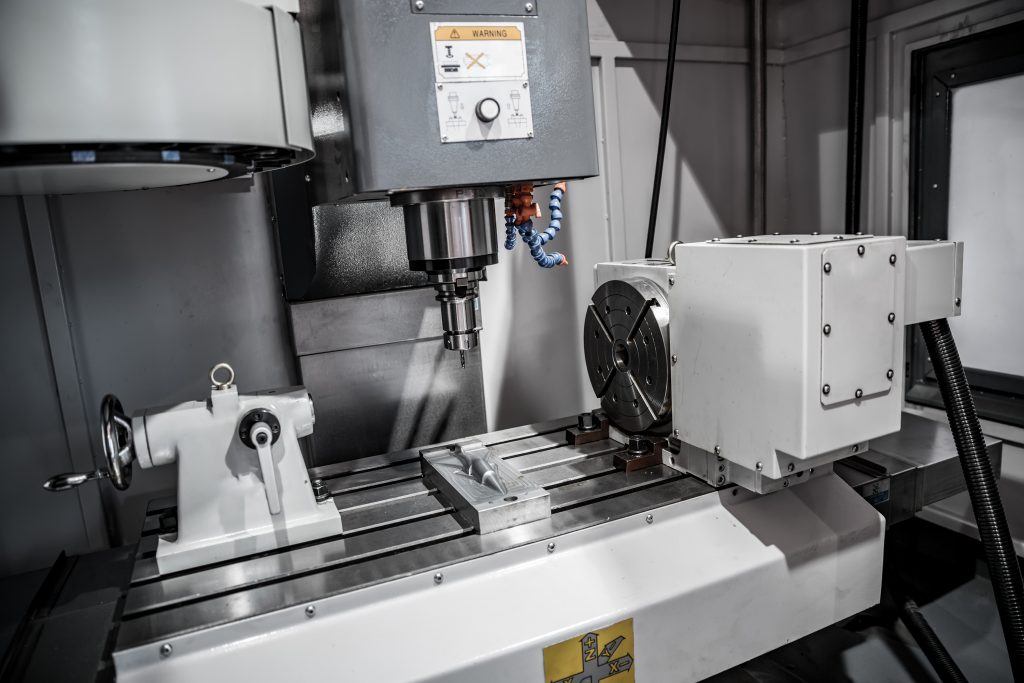

CNC milling machines

These machines use rotary cutting tools to remove material from a stationary workpiece, operating across multiple axes—typically three to five—to precisely shape flat surfaces, slots, pockets, and complex 3D contours. The cutting tools rotate at high speed while moving along programmed paths, allowing for controlled engagement with the material and exceptional dimensional accuracy. Depending on the configuration, CNC mills can perform a wide range of operations including facing, contouring, drilling, and pocketing—all in one setup.

Their flexibility makes them indispensable across industries such as aerospace, medical, automotive, and mold-making, where precision and repeatability are critical. CNC milling machines can process virtually any machinable material, from lightweight aluminum to hardened tool steels and advanced composites. They are often used to produce engine components, molds, dies, and intricate housings that demand both strength and fine detail.

Modern vertical and horizontal machining centers (VMCs and HMCs) expand these capabilities even further. Equipped with automatic tool changers, pallet changers, and multi-axis systems, they allow continuous, unattended operation and complex geometry machining from multiple angles. Some advanced 5-axis mills can machine entire parts in a single cycle, drastically reducing setup time and improving overall efficiency.

CNC lathes and turning centers

Lathes rotate the workpiece while a stationary or linearly moving cutting tool removes material to form cylindrical, conical, or contoured shapes. The constant rotation of the workpiece enables uniform cutting and precise control over diameters, making lathes ideal for manufacturing shafts, bushings, threads, and other round components that require high concentricity and surface finish. Depending on the operation, the tool can feed parallel to the axis for turning, perpendicular for facing, or at an angle for taper machining.

CNC turning centers build on the principles of traditional lathes but with full automation and multi-axis capability. These machines can execute complex machining sequences through pre-programmed toolpaths, ensuring high accuracy and repeatability across production runs. Modern systems incorporate features like live tooling, sub-spindles, and Y-axis movement—enabling secondary operations such as drilling, tapping, slotting, and milling within a single setup. This reduces the need for part transfers between machines, minimizing handling errors and cycle times.

Thanks to their efficiency, CNC lathes are widely used in industries like automotive, aerospace, energy, and medical manufacturing, producing components such as valve stems, hydraulic fittings, and precision connectors. Their ability to maintain tight tolerances, combined with advanced automation options like bar feeders and robotic loaders, makes them a cornerstone of modern high-volume and high-precision production environments.

CNC drilling machines

These machines specialize in creating holes with exceptional accuracy and consistency, controlling depth, spacing, and angle with high precision. Unlike manual drilling, CNC drilling machines automate every movement, ensuring each hole meets exact dimensional and positional tolerances. They are capable of producing everything from simple through-holes to complex patterns involving countersinking, tapping, and reaming. This precision makes them indispensable in industries such as aerospace, electronics, and automotive manufacturing—where even the smallest misalignment can compromise assembly or performance, emphasizing the importance of CNC equipment.

While milling machines can perform drilling operations, dedicated CNC drilling centers are optimized for speed, repeatability, and efficiency. They often feature automatic tool changers, high-speed spindles, and multi-spindle heads that can produce multiple holes simultaneously, significantly reducing cycle times. Some models include rotary tables or indexing fixtures to drill at various angles or on multiple faces of a part without reclamping.

Advanced CNC drilling machines also integrate probing and feedback systems to monitor tool wear and automatically adjust parameters mid-cycle, ensuring consistent quality across long production runs. Their ability to combine precision with productivity makes them vital for applications such as printed circuit board (PCB) fabrication, engine blocks, turbine components, and structural assemblies requiring tight hole patterns and consistent depths.

CNC grinding machines

Grinding systems use abrasive wheels to achieve fine surface finishes and exceptionally tight tolerances, often serving as the final finishing process on hardened materials such as steel, carbide, and ceramics. Unlike traditional cutting methods, grinding removes very small amounts of material with high precision, improving surface quality and dimensional accuracy. It’s a critical process in producing components that demand exceptional smoothness and tight geometric tolerances—often in the micrometer range.

Different types of grinders—such as surface, cylindrical, internal, and centerless—are controlled by CNC systems to maintain consistent accuracy and uniform surface texture across large batches. CNC technology allows for automated wheel dressing, compensation for tool wear, and complex contour grinding with minimal operator input. CNC grinders are indispensable in the production of gears, bearings, cutting tools, precision shafts, and aerospace components where surface integrity and part longevity are crucial.

CNC electrical discharge machines (EDM)

EDM technology removes material using controlled electrical discharges (sparks) rather than mechanical cutting forces, making it ideal for hard or delicate materials that are difficult to machine conventionally. The process involves generating a series of electrical sparks between an electrode and the workpiece, eroding material precisely without introducing mechanical stress or deformation.

Two main variants exist: wire EDM and sinker EDM. Wire EDM uses a thin, continuously fed wire—typically brass—to cut intricate shapes and contours through conductive materials with extraordinary precision. It’s often used in tool and die manufacturing, where tight tolerances and sharp internal corners are required. Sinker EDM, on the other hand, employs a shaped electrode to form complex cavities, making it ideal for mold-making, aerospace components, and medical tooling.

Modern CNC EDM systems feature automated tool changers, dielectric fluid management, and adaptive spark control to ensure consistent erosion rates and superior surface quality. Their ability to machine hardened steels and exotic alloys with micron-level precision has made EDM an essential process in high-end precision engineering.

CNC laser cutting machines

By using a concentrated laser beam, these machines cut, engrave, or mark materials with exceptional precision and minimal waste. The laser’s intense, focused energy melts, burns, or vaporizes the material along a programmed path, producing clean, burr-free edges without physical contact or tool wear. This non-contact process not only enhances accuracy but also reduces the need for post-processing, making it ideal for intricate or delicate components.

Laser cutting is widely used in industries such as sheet metal fabrication, electronics, and signage, where complex contours and fine details are required. The process works effectively on a broad range of materials including steel, stainless steel, aluminum, copper, and composites, as well as non-metals like plastics, wood, and ceramics. Advanced CNC laser cutters feature multi-axis capability, automatic focus adjustment, and high-speed motion control for consistent results across varying material thicknesses.

Modern machines often integrate automated material handling systems, nesting software, and real-time process monitoring to maximize throughput and minimize downtime. With their combination of precision, efficiency, and versatility, CNC laser cutting machines have become a cornerstone of modern digital manufacturing and prototyping workflows.

CNC plasma cutting machines

Using a high-velocity jet of ionized gas, plasma cutters rapidly slice through conductive metals such as steel, stainless steel, aluminum, and copper with impressive speed and efficiency. The plasma arc—formed when gas is superheated to extreme temperatures—melts the material, while the high-velocity stream blows the molten metal away, producing a clean, precise cut. This combination of speed and power makes plasma cutting particularly well-suited for medium- to heavy-gauge materials where productivity and cost control are key.

While plasma cutting may not match the ultra-fine precision of laser systems, it excels in industrial environments that demand fast, durable results over decorative or intricate details. It is commonly used in fabrication shops, shipbuilding, construction, and heavy equipment manufacturing to produce components such as frames, brackets, and structural panels. Modern CNC plasma cutting machines incorporate advanced motion control, automatic torch height adjustment, and high-definition plasma systems to improve edge quality and minimize dross.

Many systems also feature integrated nesting software and multi-axis cutting capabilities, allowing complex shapes to be cut efficiently from sheet stock with minimal material waste. This blend of speed, flexibility, and affordability makes CNC plasma cutting a go-to technology for large-scale metal fabrication operations.

CNC waterjet cutting machines

These systems cut materials using an ultra–high-pressure jet of water—often exceeding 60,000 psi—mixed with fine abrasive particles such as garnet. The waterjet stream erodes material along a precisely controlled path, allowing for accurate, smooth cuts without introducing heat or mechanical stress. Because no thermal distortion occurs, the process preserves the structural integrity and properties of the material, making it ideal for sensitive or heat-prone materials like composites, titanium, glass, and ceramics.

Waterjet cutting offers exceptional versatility, capable of machining virtually any material—from metals and plastics to stone and laminates—with consistent precision. It is particularly valued in industries like aerospace, architecture, and custom fabrication, where both aesthetic and functional quality are critical.

Modern CNC waterjet systems feature multi-axis capability, enabling complex 3D contouring and beveled cuts in a single setup. Integrated nesting software and automated pressure control further enhance efficiency by optimizing material usage and adjusting cutting parameters in real time. The result is a highly precise, eco-friendly cutting solution that combines flexibility, accuracy, and minimal waste for high-performance manufacturing.

CNC routers

Routers function similarly to milling machines but are specifically designed for cutting and shaping softer materials such as wood, plastics, foam, and composites. They operate at very high spindle speeds, enabling smooth, clean cuts even at fast feed rates. Their ability to handle large workpieces and intricate contours makes them ideal for industries such as furniture manufacturing, cabinetry, signage, and product prototyping.

The large working envelope and lightweight construction of CNC routers allow for high-speed machining of complex shapes, patterns, and 3D reliefs. They can perform a range of operations—such as cutting, engraving, pocketing, and contouring—with exceptional repeatability and precision.

Modern CNC routers come equipped with vacuum hold-down tables for secure material clamping, automatic tool changers for seamless multi-tool operations, and dust extraction systems to maintain clean work environments. Advanced models may also feature multi-axis control for machining complex geometries and curved surfaces in a single setup. This combination of speed, accuracy, and versatility makes CNC routers indispensable tools in both industrial and creative manufacturing applications.

CNC multitasking machines

These hybrid systems combine multiple machining capabilities—such as turning, milling, drilling, tapping, and even grinding—into a single integrated platform. By performing several operations within one setup, they eliminate the need for part transfers between machines, significantly reducing setup time, handling errors, and overall production cycles. This seamless workflow improves dimensional accuracy and ensures that critical features align perfectly, even on highly complex components.

Multitasking machines are designed to handle intricate, high-precision parts that require multiple machining processes, making them indispensable in aerospace, medical device, and precision engineering industries. Their advanced configurations often include multi-axis capability (Y-, B-, and C-axis), live tooling, and sub-spindles that allow simultaneous machining on multiple surfaces.

Modern CNC multitasking centers are equipped with intelligent control systems capable of managing complex toolpaths, adaptive cutting conditions, and real-time process monitoring. This integration of versatility and automation allows manufacturers to produce intricate, high-value components with unmatched efficiency, representing the pinnacle of CNC productivity and precision in modern manufacturing.

Find the best type of CNC machine for yourself

CNC machines represent the perfect balance between engineering innovation and manufacturing efficiency. Each type—from milling and turning to cutting and multitasking systems—serves a specific role in producing parts with precision, speed, and consistency. As automation, connectivity, and intelligent control continue to advance, CNC technology will only grow more capable and adaptable. Together, these machines form the backbone of modern industry, driving progress in design, production, and performance worldwide.